Our expertise

Boost your performance with

state-of-the-art Riblet technology

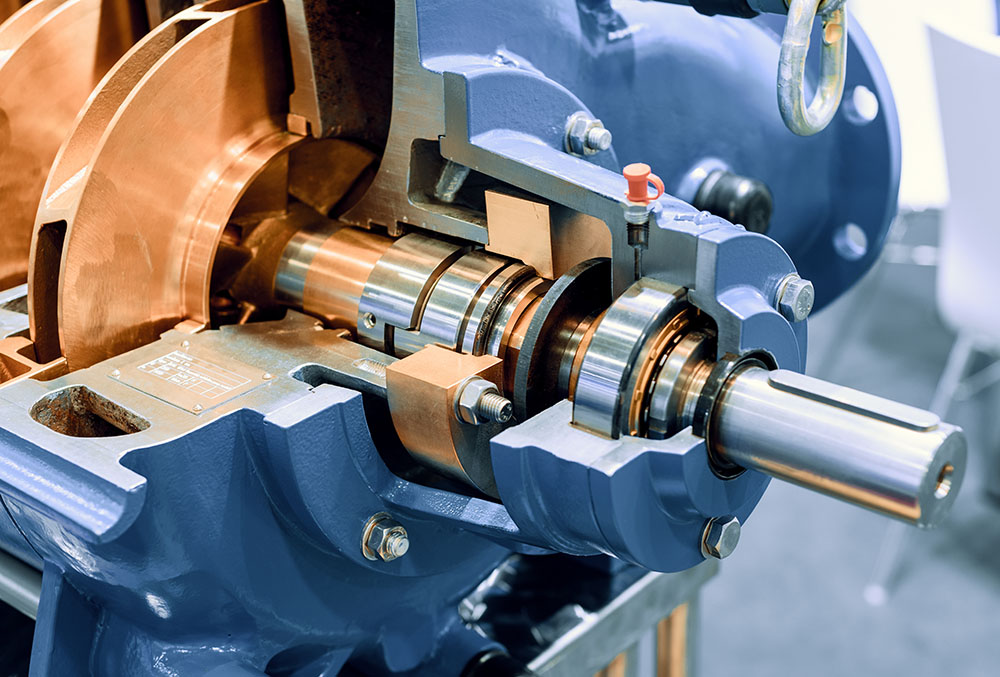

Riblet surfaces are the state-of-the-art technology within the industrial field of energy, due to the enormous potential for efficiency increases. Adopting the micro structured surfaces, individually designed for the specific application case to reach highest performance gains, brings up to 8% of fluid-dynamic drag reduction. Corresponding benefits of Riblet structures regard the reduction of noise emissions or lowering mechanical stresses which results in an extended life expectancy.

01

Increase Efficiency

02

Reduce Power Consumption

03

Enhance Profitability

04

Decrease Noise Emissions

Fuel savings and cut down on CO2 emissions

01

Cut Fuel Consumptions

02

Reduce CO2 Emissions

03

Lower Noise Emissions

04

Enhance Profitability

Compete and win with Riblets by minimizing drag

01

Reduce Fluid-Dynamic Drag

02

Increase Top Speeds

03

Raise Average Speeds

04

EnhancedSafety

Moving towards a sustainable future with smart industrial solutions

01

Increase Flow Rates

02

Encourage Sustainability

03

Enhance Cost Effectiveness

04

Decrease Noise Emissions

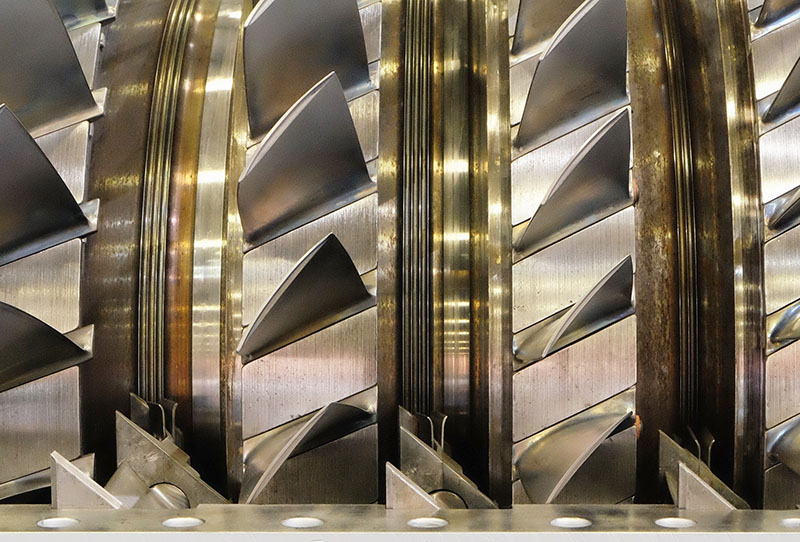

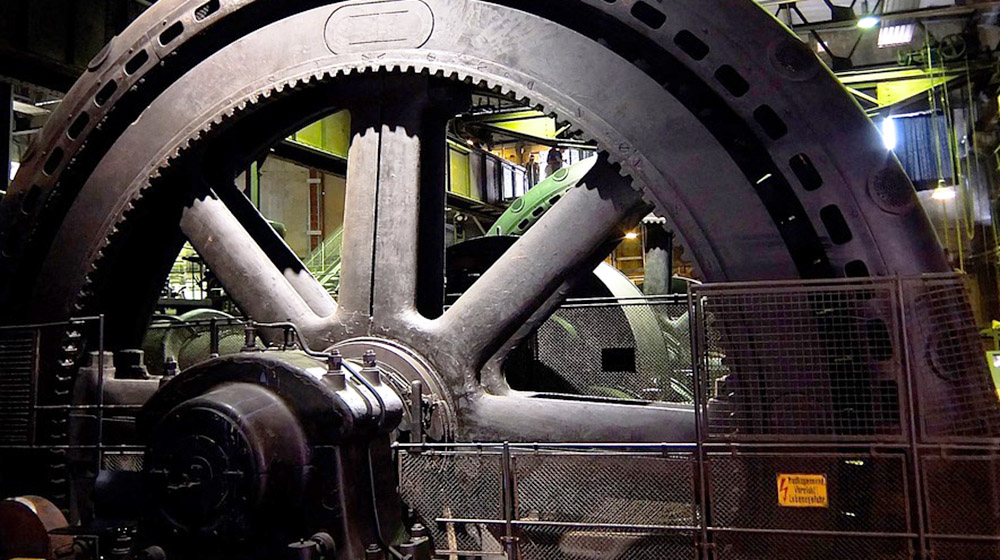

A specific application with an immense potential for performance improvements through Riblet surfaces are pipework systems in general. Practical efficiency increases near to the theoretical exploiting potential of up to 8% by the reduction of fluid dynamic friction are possible. Enormous savings in operating costs are viable by reducing pipe friction. Noise emissions resulting from turbulent flow conditions can be lowered accordingly. Other applications and possible performance improvements concern for instance flywheels, centrifuges or combustion processes. In the sense of efficiency increases and reduced energy consumption, Riblets are a powerful tool to encourage sustainability of industrial facilities.