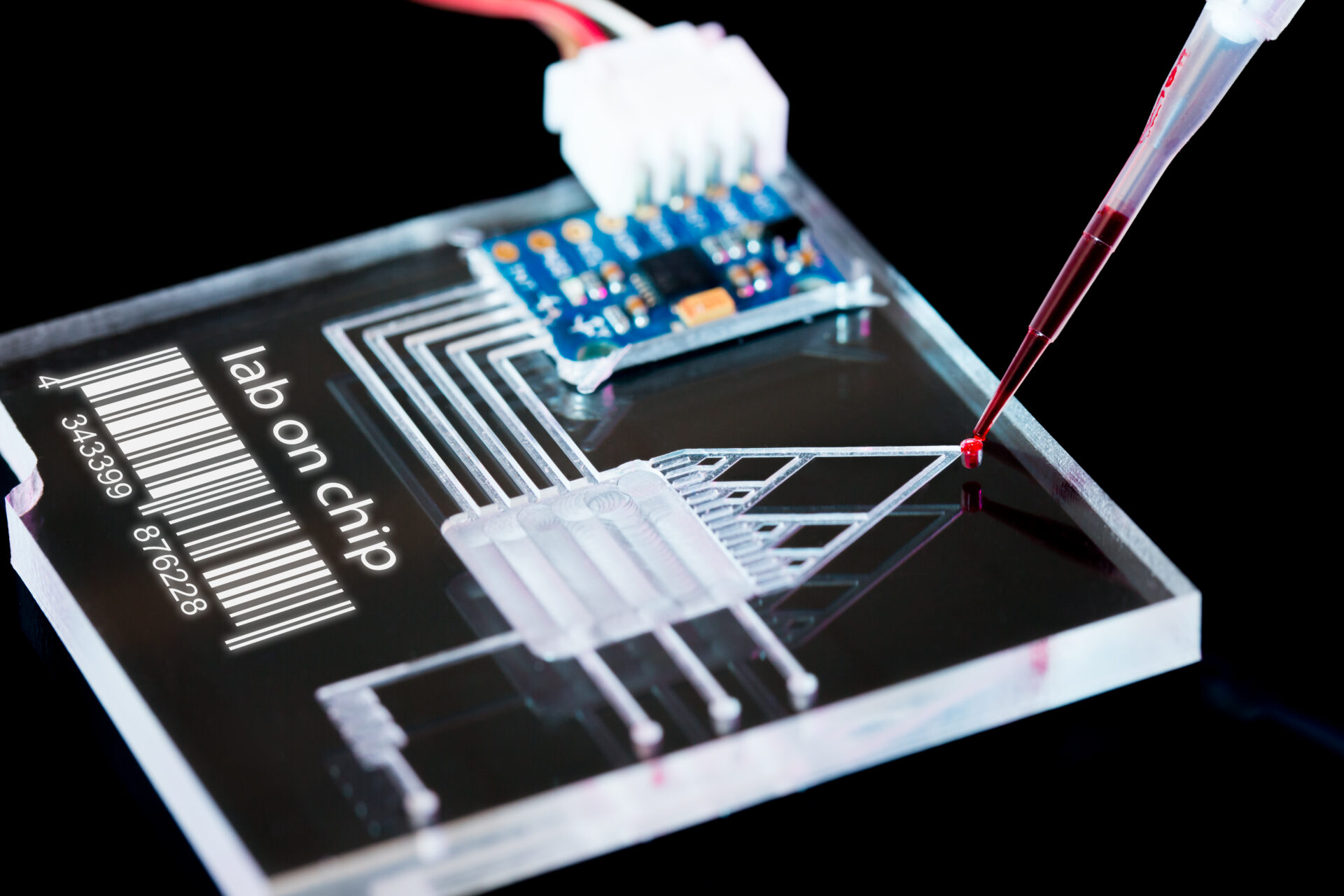

A shortcut to the world of point-of-care diagnostics: Optimization for miniaturized foil-based microfluidic chips

Task

Improvement. The chip was designed to detect pathogens/anti-bodies in a point-of-care setting. The presence of air bubbles when filling the chip with a fluid was investigated.

Solution

Verification of several hypothesis what causes the air bubbles by means of numerical simulation. The theory that spots in the fluid channel resulted from sudden contact angle changes proved true.

Benefit

No need to run several expensive and time-consuming test series to find out the cause as the simulation yielded an unambiguous result.

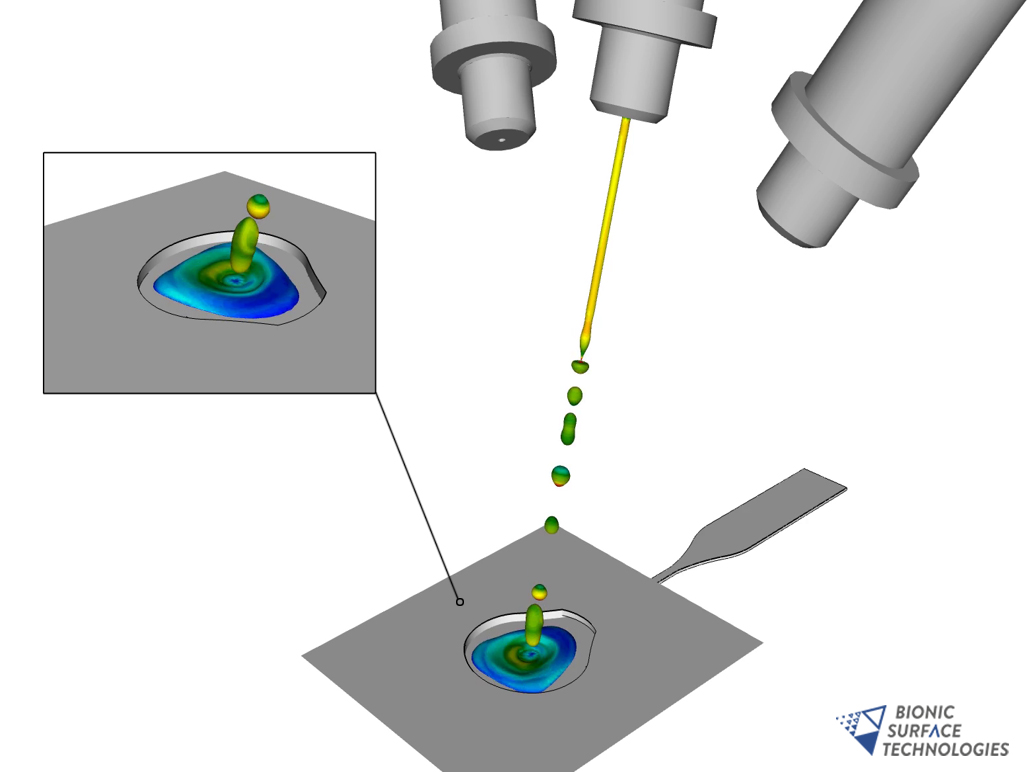

Cause studies can be carried out by testing theory by theory in-situ. The smarter and more cost-efficient way is to run individual simulations. Simulating has the huge advantage that you can verify different hypothesis without running any test at all. Thus, limiting the time and cost amount spent on testing capacities considerably. In the present case the microfluidic chip consisted of multi-layered foils. As the foils had either hydrophobic or hydrophilic characteristics small defects in the laminating layer in the manufacturing process produced irritations. The air bubbles therefore were a result of hydrophobicity as the microfluidic flow rose in the fluid channel with hydrophilic properties due to the capillary effect. Even small areas with surface defects in the laminate layer produced the well-known lotus effect. The fluid flowed faster sideways on the hydrophilic solid surface whereas it flushed around the air bubbles, as the illustration below clearly shows. By means of simulation we proved true that changes in the contact angle of the surface were responsible for the air entrapment – the bubbles.