Riblets in aeronautics –

the sky is the limit

Task

Unfold the full potential of Riblets by identifying alternative areas on aircrafts suitable for applying Riblets.

Solution

Change of Riblet application area to reduce drag and improve lift.

Benefit

Fuel savings and thus cost cutting.

Boeing 777-300

Project details

1,200 tons of carbon dioxide and 400 tons of jet fuel per long-range aircraft – that’s SWISS`s annual cut down on CO2 emissions and fuel and a promising start! However, taking advantage of Riblet films in aeronautics offers a huge potential as there is still air to the top. Within the last few years, the usage of Riblets on the fuselage has established itself as state-of-the-art. Several carriers trust in Riblets to cut down costs for cargo flights. Swiss is the first passenger airline in the world to utilize the innovative Riblets technology on its long-haul flights to enhance the Boeing 777-300’s aerodynamics to further reduce the carbon dioxide emissions and the fuel consumption. The usage of a Riblet foils cut SWISS’ annual fuel consumption substantially. Boosting Riblets in aeronautics to unfold the full potential of this technology is key to drive forward innovation as today cutting costs and minimizing Co2 consumption are the order of the day in every field and even more in the high-competitive sector of aeronautics.

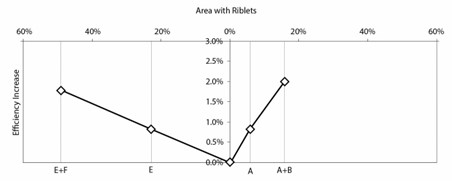

We at BST lean forward to the next venture beneath the skies and take a closer look on Riblet application costs and sustainability. Various factors affect the results: the application technology, area, material, and size of the aircraft as well as its impact on different aircrafts belonging to a certain airliner fleet. The project objective was to identify the most cost-effective and performance-efficient area of an aircraft to apply Riblets in terms of investment-benefit ratio. BST aimed to demonstrate that with a much smaller percentage of the total area of the airplane the same Riblet effect in terms of drag reduction could be generated, making Riblets even more attractive for the industry. The project was realized by designing a suitable Riblet geometry which was then used as a basis to run a numerical simulation. The analysis showed that applying Riblets on the main wing suction side rather than on the belly of the fuselage had the same impact. Thus, limiting the Riblets on 5 percent of the total aircraft area instead of using Riblets on 20 percent of the area (located on the fuselage) improved efficiency in the same extend.

Outcome

We found out that applying the Riblets on a defined, small area of the wing has the same impact as coating the entire fuselage with Riblets when it comes to fuel savings. The study aimed at establishing a best practice on the use of Riblets in the airline industry that is as efficient as possible in terms of investment-benefit-ratio.