One, two, three, GO!

Task

Reduction of aerodynamic drag. Time gain of a few hundredths in Olympic racing sports.

Solution

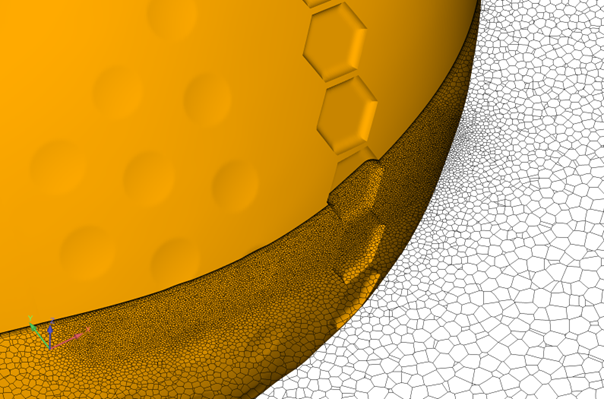

Re-design of racing suits by applying surface structure modifications at pre-defined areas of the suits.

Benefit

A tremendous reduction of aerodynamic drag by 4.2 percent achieved by using the tear-off edge effect.

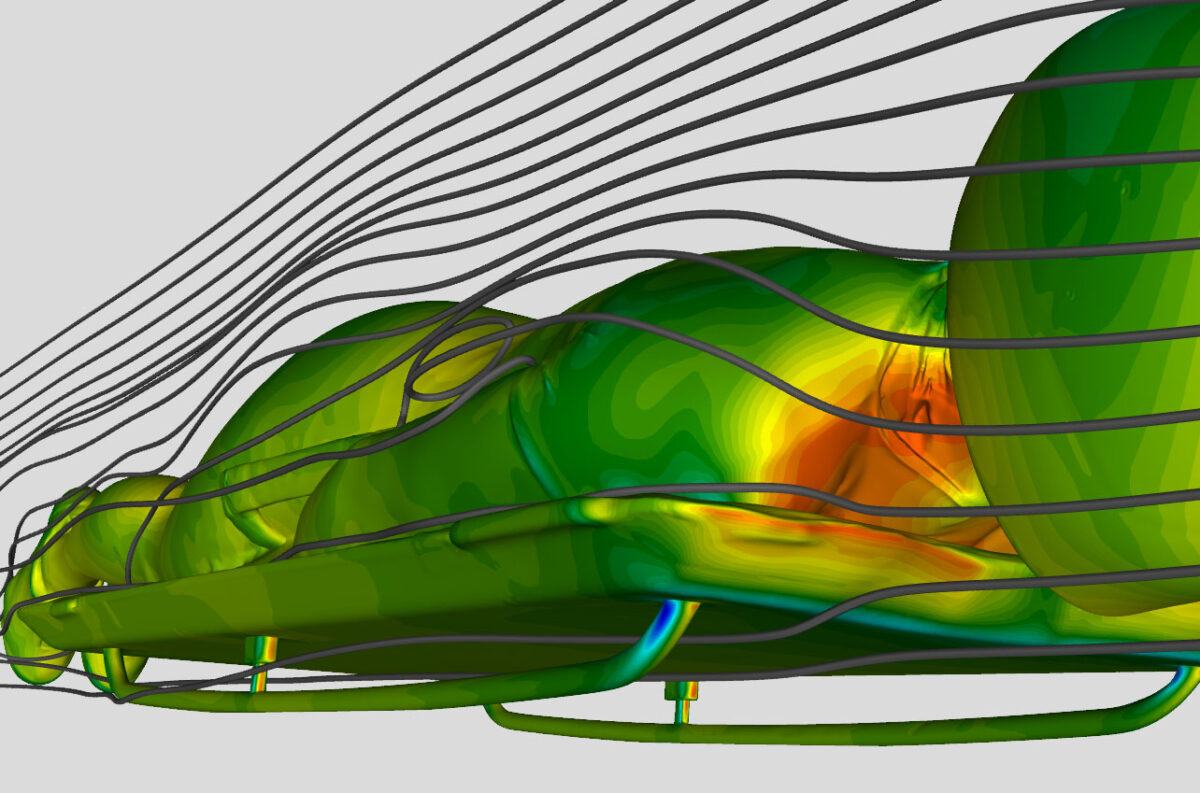

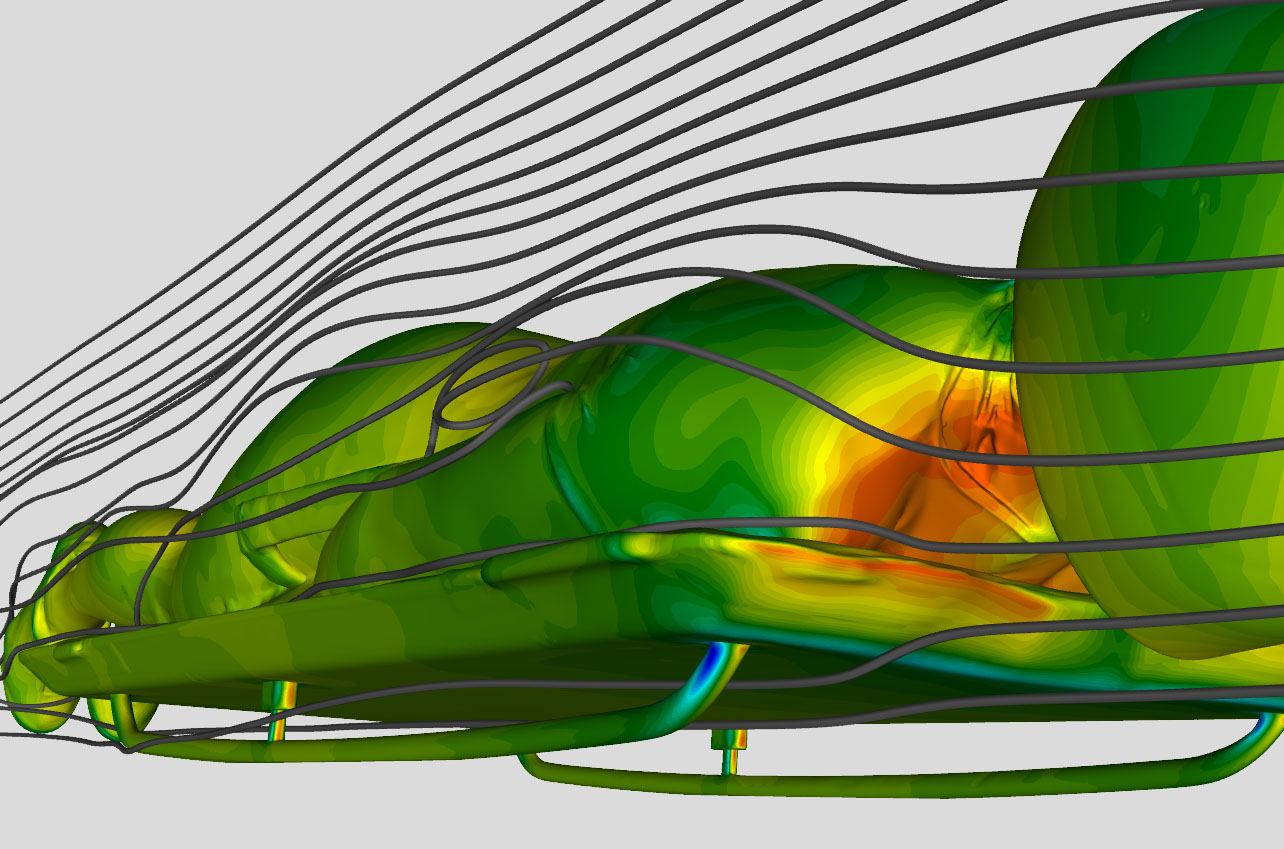

Functional surfaces are of paramount engineering importance as they allow us, for example, to modify the surface of a material to improve its properties or to achieve new functionalities that the base material does not have. Positive effects can be reached by dimples or by the tear-off edge effect. Edges in surfaces of blunt bodies cause flow separation at certain points. Intentionally produced changes of the direction and position of the detachment of the boundary layer from the surface into a wake can have positive or negative effects. The scope is to reduce the air resistance by achieving that the flow around the object changes propitiously. Whether an earlier or later separation on a certain area is favorable can be determined by conducting numerical simulations. We calculated the applicable flow dynamics for the racing suits and minimized the separation zone by adding a concave structure that induced a flow separation in the area. Finally, GRDXKN printed the concave surface structure on the racing suits. The optimized surface structure reduced the air resistance and enhanced the aerodynamic performance considerably. This aerodynamically effective tear-off edge yielded an incredible reduction of 4,2 percent.

Bionic surface technologies GmbH and GRDXKN, created in close co-operation specialized racing suits, designed to support the aerodynamic properties. We optimized the contours of the racing suits on certain, pre-defined areas reaching a positive effect by minimizing the separation. Amazingly the change yielded a reduction of 4,2 percent giving the athletes a technical advantage over the competitors