Revolutionizing turbomachine efficiency with Riblet surfaces

While the effectiveness of Riblets as passive devices for drag reduction is well-established, a comprehensive verification of their capabilities in specific applications is often lacking due to associated challenges of extensive and valid experiments, the absence of suitable numerical models, and the need for appropriate materials. Therefore, the project focused on developing durable surface materials capable of withstanding harsh conditions, as well as innovative manufacturing technologies for implementing nanostructures and nanoparticles. Two demonstrator lines were established to validate their effectiveness.

The project involved ten partners from six countries, including industry actors, research centres, and universities. Led by the coordinator bionic surface technologies GmbH from Austria, the other participants who collaborated to succeed in the project’s goals were RINA (Italy), Fraunhofer-IFAM (Germany), IDONIAL (Spain), General Electric (Germany), Lufthansa Technik (Germany), MAN Energy Solutions (Switzerland), Nanto Cleantech (Israel), RWTH Aachen University (Germany), and Graz University of Technology (Austria).

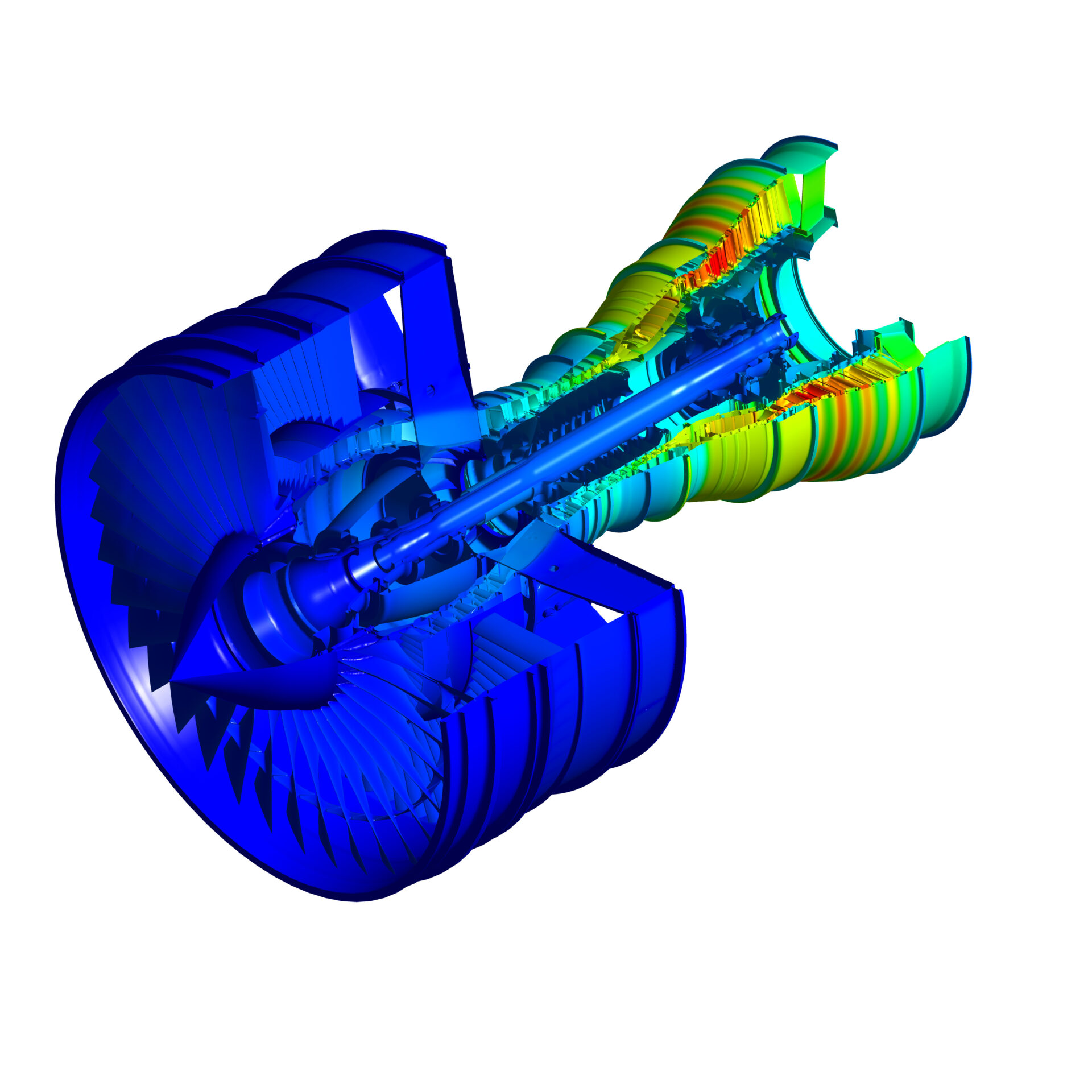

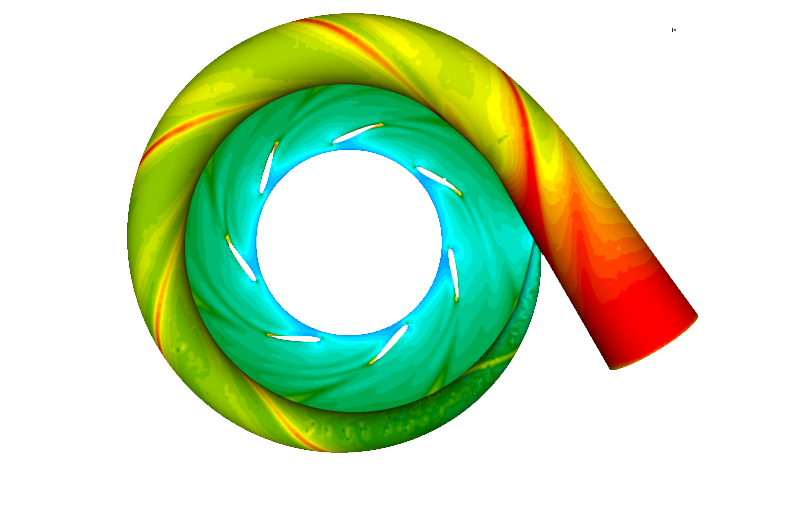

Throughout the project, the emphasis was on producing large-scale high ReSiSTant Riblet surfaces on two testing units and demonstrating a complete fabrication chain for the two selected application demonstrators in the distinct fields of aircraft turbofans and industrial compressors.

At bionic surface technologies GmbH, our focus was on conducting advanced Computational Fluid Dynamic analyses (CFD) to obtain specific and meaningful data for designing further procedures. Precise simulations were performed to evaluate the benefits of Riblets in turbofan jet engines and industrial compressors. Feasibility studies, including material evaluation studies, were conducted for all demonstrators. The results of the CFD simulations revealed harsh temperature and wall shear stress conditions in both demonstrators, which was considered in the Riblet design and material development.

According to the simulations, a potential increase of around 2% of torque on the turbine was predicted for the turbofan engine. Regarding the compressor, a possible efficiency increase of around 2.5% was forecasted. The experiments on the test rig showed an efficiency increase of over 1% by applied Riblets on the volute.

Significant progress was made in developing a Riblet coating application during the ReSiSTant project. Two new molds were created to facilitate the production of Riblets with consistent sizes on specific and complex surfaces.However, finding the optimal balance between the manufacturable Riblet size and the ideal Riblet size for the involved machines was a crucial consideration.

Overall, the ReSiSTant project made significant advancements in the development and application of Riblets for drag reductions in turbomachines, paving the way for enhanced efficiency and environmental benefits in various industries.