High five for High-G-Turns

Task

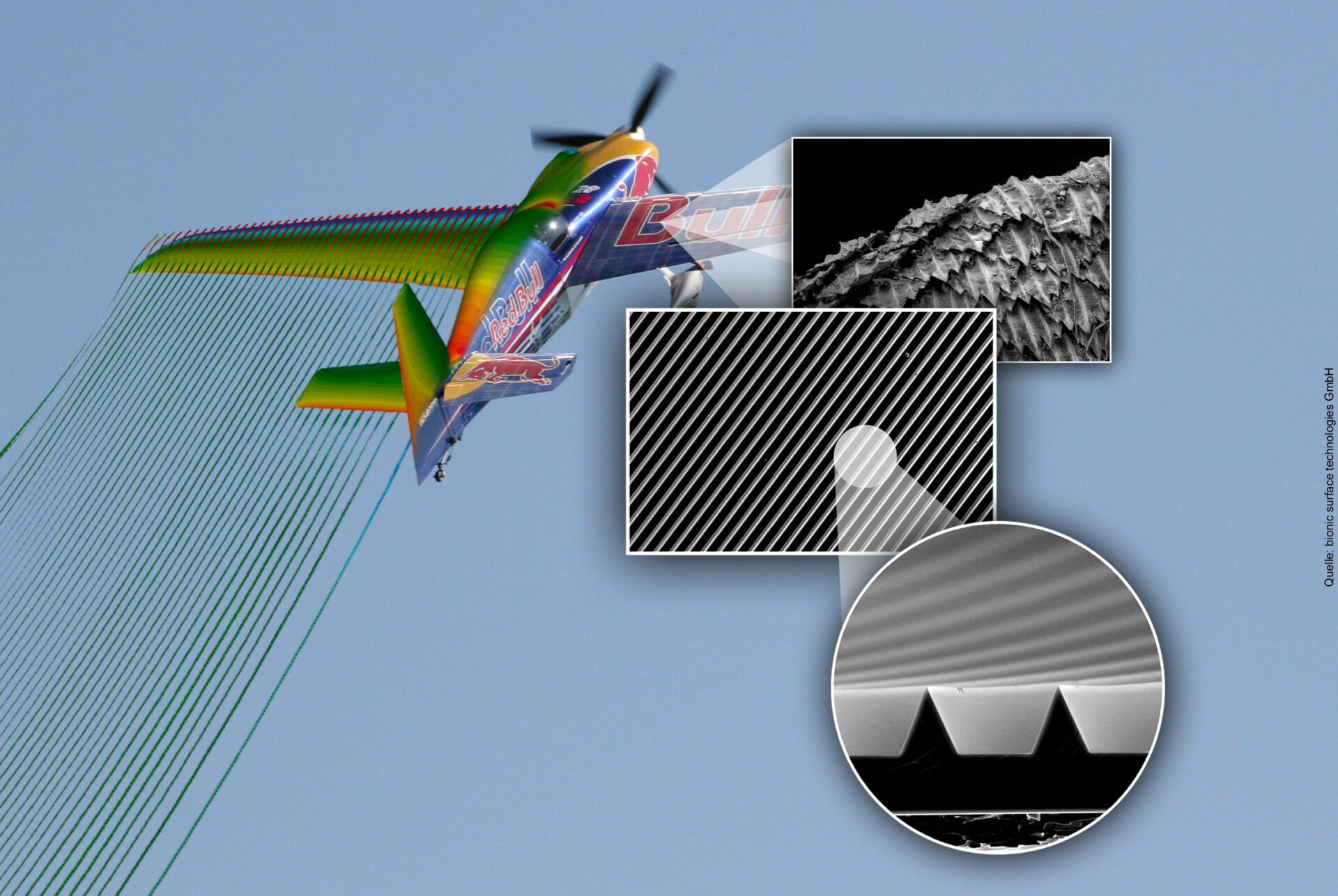

Improvement of aerodynamical efficiency by modifications on the aircraft.

Solution

Riblet engineering, Riblet design and application of Riblets on the wings.

Benefit

Improvement of aerodynamical efficiency resulting in more lift, less drag, higher speed, delayed stall, and an increased level of safety.

By numerical CFD simulation and Riblet engineering we designed the optimal Riblets for the application on the wings. So various Riblet structures could be tested in advance to select the best to reduce frictional resistance. By applying those micro- and nanostructured surfaces, which are modeled on nature, to flow-relevant parts of the airfoils, a 4% increase in efficiency could be assured and even more important, safety aspects on High-G-Turns were addressed. Riblets ensure safer flight maneuvers as they reduce the risk of stall while performing a High-G-Turn. It´s a well-known physical phenomenon that at high speeds when the angle of attack is too steep, the boundary layer detaches from the airfoil and the flow tears off. The aircraft loses lift and starts to spin. Due to the tailor-made Riblets on the wings the flow continuous for much longer and the separation starts later. Therefore, we calculated the applicable flow dynamics for minimizing the risk of stall and to postpone the separation of the flow by adding Riblets on the wings.